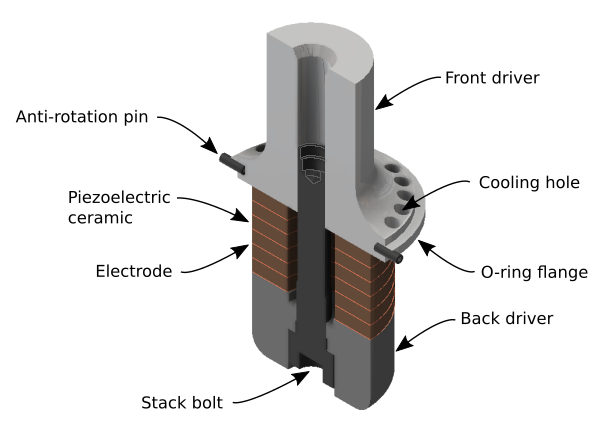

The masses and crystals are fixed between a centre post and a clamping ring (as preload).Ĭraig Aszkler, in Sensor Technology Handbook, 2005 IEPE Accelerometers 8.5C and D contains four crystals mounted on a rectangular post. The shear-type accelerometer shown in Fig. Moreover some compensation for common interferences is achieved. In this configuration the crystals are electrically in parallel and mechanically in series, resulting in a doubled sensitivity. One electrode is connected to the common surface of the crystals, the other to the housing. This example comprises two crystals, mounted back to back between the seismic mass and the base plate. 8.5B shows a compression mode accelerometer. Here, also, the mass is fixed by a preload onto the crystal. For applications where pressure has to be measured in a vibrating or otherwise moving environment, special pressure sensors are designed with a compensating crystal, to minimize the acceleration sensitivity.Īn accelerometer consists basically of one or more piezoelectric crystals and a proof mass (or seismic mass). Piezoelectric pressure sensors are also sensitive to acceleration, because the mass of the housing produces an inertial force on the crystal when accelerated. The total force on the membrane – that is the pressure times the active area of the membrane – is mechanically transferred to the crystal. In a piezoelectric pressure sensor the pressure to be measured is applied to a thin metal membrane. Usually the case acts as the ground terminal. Obviously the construction provides a means to connect the electrodes of the crystal to an external connector (not shown in the figure).

8.5A) the force to be measured is directly transferred to the piezoelectric crystal. Principle of piezoelectric sensors (A) force sensor (longitudinal), (B) compression type accelerometer, (C) shear-type accelerometer, (D) top view of (C) the arrows show the main axis of sensitivity electrical terminals are not shown. Fortunately as long as these changes are slow, they would not limit the applicability because of the previously discussed intrinsic high-pass character.įigure 8.5. Further when materials connected to the piezoelectric crystals have different thermal expansion coefficients (for instance clamping parts and electrodes), the crystal experiences unwanted forces. Secondly a temperature change may induce crystal deformation and hence an electrical output as well. First piezoelectric materials are pyroelectric, so they also respond to temperature changes. There are various causes for this temperature effect. This makes the sensor behave as a high-pass filter for input signals, impeding pure static measurements.Ī further point of attention is the temperature sensitivity. The surface charge produced by an applied force might be neutralized easily by charges from the environment (airborne charges), by current leakage (due to a non-zero conductivity of the dielectric) or just by the input resistance of the connected electronics (discussed further in Section 8.3). Piezoelectric sensors have disadvantages, too. Although force is the primary quantity that is measured by a piezoelectric sensor, other quantities such as pressure, strain, and acceleration can easily be measured as well, using a proper construction. A piezoelectric force sensor, on the other hand, responds directly to an applied force: the associated deformation is in most cases negligibly small, assuring small loading errors in the force measurement. Such a large displacement, however, could unintentionally affect the structure in which the force has to be measured. A high sensitivity requires a large deformation, which is achieved by a low stiffness of the spring element. The elasticity of the spring element determines the sensitivity of such sensors.

Most force sensors are based on an elastic or spring element: the force generates a deformation that is measured by some displacement sensor (as discussed in previous chapters). Paul Regtien, Edwin Dertien, in Sensors for Mechatronics (Second Edition), 2018 8.2 Force, pressure, and acceleration sensors 8.2.1 Construction

0 kommentar(er)

0 kommentar(er)